What is Tyvek material?

What is Tyvek?

Tyvek is a unique and versatile synthetic material known for its strength, lightness, and resistance to water and chemicals. It is made from polyethylene fibers, which are a type of thermoplastic, and the material is both lightweight and durable, making it popular for a wide range of applications. Tyvek is a non-woven material produced from high-density polyethylene (HDPE). This means that it is not woven like traditional textiles but instead consists of a continuous mass of fine fibers bonded together through heat and pressure. This gives Tyvek its unique properties: it is water-resistant but simultaneously allows moisture and vapor to pass through, making it breathable. It is also resistant to tearing forces, UV radiation, and chemical substances.

The production of Tyvek begins with melting polyethylene. The material starts as small pellets of high-density polyethylene, which are heated until they melt into a liquid form. This molten polyethylene is then pressed through fine nozzles, creating fibers that cool and solidify quickly as they meet cold air. These fibers are extremely thin—much finer than hair—and form the basis of Tyvek. The fibers are then gathered into a cohesive sheet, which is bonded together under heat and pressure. Because the material is not woven but consists of compressed fibers, it gains its non-woven properties, making it both lightweight and incredibly durable and tear-resistant. Once the fibers are bonded, the material can be further treated to give specific properties, such as gloss, texture, or flexibility, depending on the desired end-use.

Tyvek is known for several characteristics that make it suitable for many different applications. It is water-resistant yet breathable, so it does not allow liquids to penetrate but allows vapor to pass. This makes it ideal for products where protection from water is important but where ventilation is still required. The material is also lightweight and tear-resistant, meaning it can withstand significant loads and tearing forces without being heavy. Additionally, Tyvek is resistant to many chemicals and solvents, making it suitable for industrial and safety applications. It is also UV-resistant, meaning it degrades slowly when exposed to sunlight, making it perfect for outdoor applications such as construction or packaging. Finally, Tyvek is recyclable. Since it is a thermoplastic material, it can be melted and recycled, making it a relatively environmentally friendly option when disposed of and recycled properly.

This manufacturing process and the synthetic origin of the material make it possible to create a material that combines functionality and durability and can be adapted to many different needs. Tyvek has thus become an indispensable part of many industries, ranging from construction to protective equipment and creative applications such as art and design.

Tyvek properties - Durability, water repellency and breathability

Tyvek is known for a number of properties that make it a popular material in many industries. The most important of these are its durability, water repellency and breathability, making it both functional and flexible.

Durability

One of Tyvek's most prominent properties is its strength and resistance to tearing and puncture. Despite its light weight, the material is extremely durable, making it suitable for both demanding industrial applications and long-term outdoor environments. This durability also makes Tyvek a cost-effective choice as it can withstand wear and tear for longer than many other materials.

Water repellent

Tyvek is water repellent, which means it effectively prevents water from penetrating. This makes it ideal for protection against the elements in applications such as construction and packaging. While protecting against water, the material remains relatively lightweight and flexible, making it easy to work with in many different industries.

Breathability

Although Tyvek repels water, it is also breathable, which means it allows water vapour to pass through. This makes it particularly suitable for construction, where it can help regulate moisture by allowing water vapour to escape while protecting against rain and wind. This property also helps prevent condensation and mould growth in structures. Tyvek wristbands used for festivals and events benefit from this durability and water repellency, making them an ideal choice for any occasion.

Pros and cons of Tyvek

Tyvek is a special material used in many industries and has both advantages and disadvantages. One of the biggest advantages of Tyvek is its durability. The material is extremely strong and resistant to tearing, making it ideal for harsh conditions such as those found in the construction industry, where it protects against water and wind. In addition, Tyvek is water repellent, ensuring that it effectively prevents water from penetrating while allowing vapour to pass through. This combination prevents moisture build-up inside and reduces the risk of mould, making Tyvek perfect for construction and outdoor use.

Tyvek is also lightweight and flexible, making it easy to work with. It can be cut, folded and moulded without breaking, making it suitable for a variety of applications. An eco-friendly benefit of Tyvek is that it is recyclable; it can be melted down and used to make new products, helping to reduce waste and environmental impact.

On the negative side, the cost of producing Tyvek is often higher than some other materials, especially for single use, which can be an important factor if budgets are tight. Although Tyvek is recyclable, it is still made from plastic, which can cause environmental impacts if not disposed of properly. Finally, the material has limited heat resistance, which means it can be damaged at high temperatures and is therefore not always suitable for extreme heat applications.

Overall, Tyvek combines many useful properties such as durability, water repellency and recyclability. It's important to consider both the pros and cons when choosing Tyvek for specific applications so you can make the best decision for your project.

What is the difference between Tyvek and other materials?

Tyvek differs significantly from paper, plastic and fabric in several ways. Paper is generally fragile and can easily tear or crumble. It is vulnerable to water as it absorbs moisture and loses its structure, which can make it unusable in humid environments. Tyvek, on the other hand, is extremely strong and tear-resistant, giving it superior durability. This strength allows Tyvek to withstand harsh conditions that paper cannot.

When comparing Tyvek to plastic, you'll notice that Tyvek is made from polyethylene, giving it both strength and flexibility. Traditional plastic is often rigid and can be vulnerable to tearing, whereas Tyvek offers a combination of strength and flexibility. In addition, Tyvek is more breathable than many plastics, allowing vapour to pass through. This is particularly important in applications where it is necessary to prevent moisture build-up.

When looking at fabric, you can see that Tyvek also has some significant advantages. Fabric may be more comfortable and flexible, but it's generally less durable and can be more susceptible to abrasion and damage. Tyvek is water repellent, which protects it from moisture and dirt, while many fabrics don't have the same protection. This water repellency makes Tyvek an ideal candidate for outdoor applications where it needs to withstand the elements. Tyvek also requires less maintenance; it is easier to clean and can often be wiped with a damp cloth, whereas fabric materials may require more careful handling and washing.

Overall, Tyvek offers unique properties compared to paper, plastic and fabric, making it an attractive choice for many different applications. Each material type has its own strengths and weaknesses, but Tyvek's combination of durability, water repellency and flexibility sets it apart from more traditional materials.

Use Tyvek for your next event or construction project

When planning your next project, whether it's a construction project or an event, it's worth considering Tyvek as your material. Tyvek offers a unique combination of durability, water repellency and flexibility that makes it ideal for a wide range of applications. Its strong and tear-resistant properties ensure it can withstand the challenges that both construction and outdoor events can bring.

In the construction industry, Tyvek works great as a protective membrane that keeps wind and water out while allowing vapour to pass through. This helps maintain a healthy indoor climate and protects the integrity of the building. It's not only practical, but also a smart investment that can save money in the long run by preventing damage.

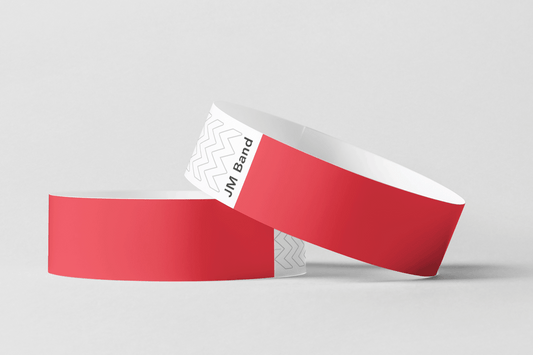

For events, such as festivals, trade shows or weddings, Tyvek is an excellent option for wristbands, signage and packaging. It's lightweight, flexible and can be printed in vibrant colours, making it an ideal choice for attracting attention and creating a memorable experience for attendees. With Tyvek, you can create a unique visual identity that will be remembered long after the event is over. Its water-repellent properties also ensure that your material remains in good condition, even in unfavourable weather conditions.

By choosing Tyvek for your next project, you are investing in a material that is both functional and stylish. It requires minimal maintenance and can be easily cleaned, making it a practical choice for busy organisers and builders. Give your project the edge it deserves and choose Tyvek. Whether it's for a build or an event, you'll find that Tyvek delivers on all fronts and helps make your project a success. You won't regret it!

Get an overview of Tyvek products from us

Explore our range of Tyvek wristbands that are perfect for festivals, events and functions. Our wristbands are durable, water-resistant and can be customised with prints to create a unique look for your next event.

Tyvek wristbands

-

Printed paper wristbands

Regular price From €0,04Regular priceUnit price / per -

Colour-printed paper wristbands

Regular price From €0,10Regular priceUnit price / per -

Paper Wristbands Print - Inquire

Regular price From €0,04Regular priceUnit price / per -

Tyvek Wristbands without print

Regular price From €0,04Regular priceUnit price / per